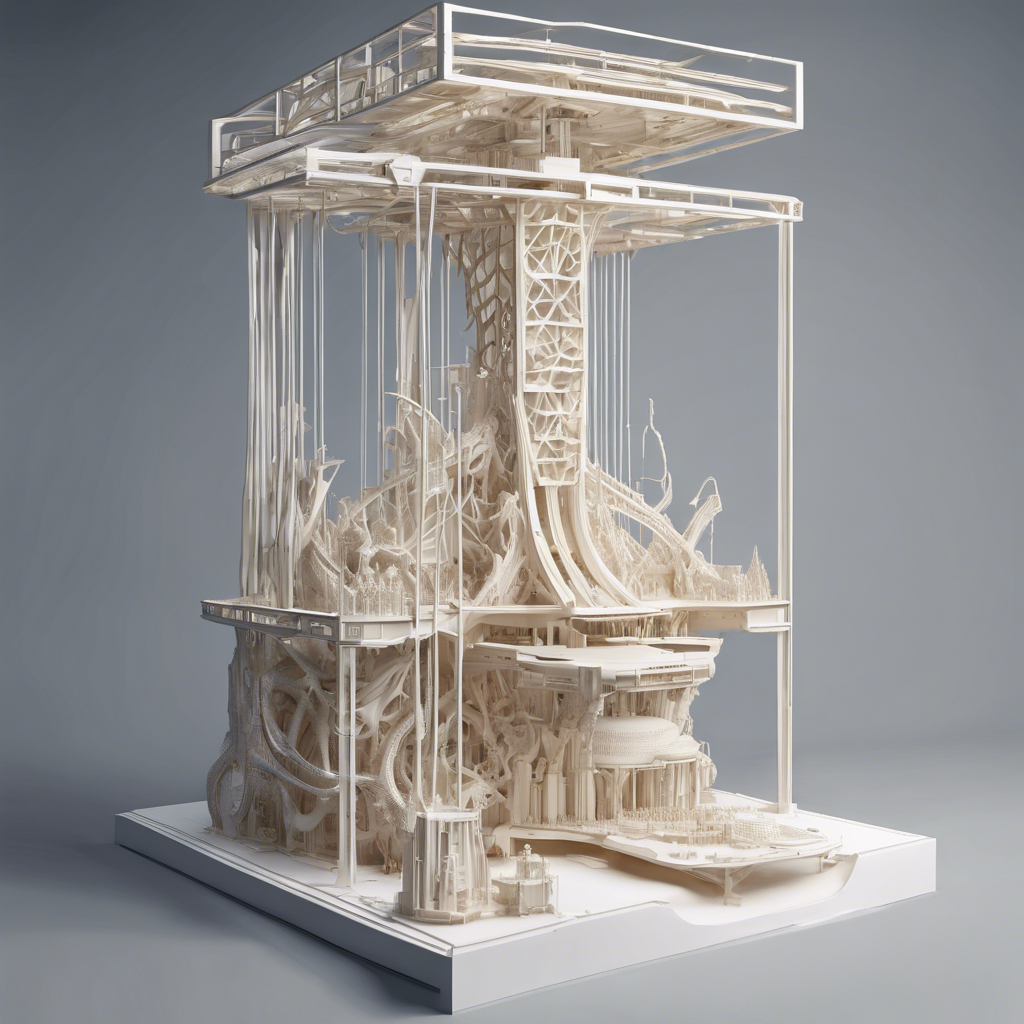

Resin printers are a type of 3D printer that uses photopolymer resin to create objects layer by layer. These printers are taking the 3D printing world by storm. Their ability to produce highly detailed models with high-quality prints is unmatched.

If you're looking to create models with intricate details, resin printers are a no-brainer.

The advantages of resin printing are clear: high resolution, large build volumes, and the ability to print functional parts.

Dive into our list of top resin printers and discover the perfect machine for your needs.

Introduction to Resin Printers

Resin printers have become increasingly popular due to their ability to produce high-quality prints.

Unlike FDM (Fused Deposition Modeling) printers, resin printers use liquid resin and UV light to create models with exceptional detail.

The print quality of resin printers is unmatched, making them ideal for creating highly detailed models.

With large build volumes and high resolution, resin printers are perfect for both hobbyists and professionals.

Resin Printers vs. FDM Printers

When comparing resin printers and FDM (Fused Deposition Modeling) printers, several factors come into play, including print quality, speed, cost, and usability. Here’s a detailed comparison:

1. Print Quality

- Resin Printers: Offer higher resolution and finer details, producing smoother surfaces and intricate designs. Ideal for miniatures, jewelry, and detailed prototypes.

- FDM Printers: Generally produce lower resolution prints with visible layer lines. Suitable for functional parts but may require post-processing for a smoother finish.

2. Material Types

- Resin Printers: Use liquid photopolymer resins that cure under UV light. There are various specialized resins available, including flexible, tough, and castable options.

- FDM Printers: Use thermoplastic filaments like PLA, ABS, PETG, and TPU. Each material has different properties, making them suitable for various applications.

3. Print Speed

- Resin Printers: These can be faster for small, detailed prints due to their layer curing process. However, post-processing (washing and curing) can add time.

- FDM Printers: Generally slower, especially for complex models, but can print larger objects more efficiently without extensive post-processing.

4. Ease of Use

- Resin Printers: Require careful handling of resins, including safety precautions due to their chemical nature. Post-processing is also necessary.

- FDM Printers: Often more user-friendly, with simpler setup and operation. Filament loading and printing processes are straightforward.

5. Cost

- Resin Printers: Typically have a higher initial cost and ongoing material costs due to the price of resins. However, they can produce high-value items.

- FDM Printers: Generally more affordable upfront, with lower material costs for filaments, making them accessible for hobbyists and small businesses.

6. Durability and Strength

- Resin Printers: Prints can be brittle, depending on the resin used. Some specialized resins offer improved toughness.

- FDM Printers: Prints are often more durable and can withstand mechanical stress, making them suitable for functional parts.

7. Applications

- Resin Printers: Best for applications requiring high detail, such as dental models, prototypes, and artistic projects.

- FDM Printers: Ideal for functional prototypes, mechanical parts, and larger prints where detail is less critical.

The choice between resin and FDM printers depends on your specific needs. If you prioritize high detail and surface finish, resin printers are the way to go. However, if you need durability, ease of use, and cost-effectiveness for larger prints, FDM printers may be more suitable.

1. Uniformation 8K Resin 3D Printer GKtwo

The 8K Resin 3D Printer GKtwo is a powerhouse in the resin printing market. With a 10.3'' LCD and a large build volume of 228 128 H245mm, this printer is perfect for creating large parts or multiple smaller models at once.

Exclusive Insights

The GKtwo boasts an 8K monochrome screen, providing high resolution and smooth surfaces for your resin prints. The built-in heating system ensures consistent print quality, even in colder environments.

Additionally, the odor removal filter makes resin printing more pleasant by reducing harmful odors.

The GKtwo is compatible with all the latest slicers, including Chitubox and UniFormation slicer.

This high compatibility ensures that you can use different materials and achieve the best print quality possible.

Customer Review

"I've been using the GKtwo for a few months now, and it's been a game changer for my resin printing projects. The high resolution and large build volume allow me to create highly detailed models with ease. The built-in heating system and odor filter are extremely helpful, making the printing process much more enjoyable." - Sarah

High Resolution and Large Build Volume

Uniformation 8K Resin 3D Printer

2. ELEGOO Jupiter SE

The ELEGOO Jupiter SE is a top choice for those looking to print large format models. With a 12.8-inch 6K monochrome LCD and a printing size of 10.94 x 6.15 x 11.81 inches, this printer offers ample space for ambitious projects.

Exclusive Insights

The Jupiter SE's 6K monochrome LCD ensures high-quality prints with stunning detail. The automatic resin feeding and recycling system reduces waste and saves money, making it an affordable option for large format printing.

The efficient cooling system and upgraded carbon filter ensure a stable printing environment and reduce harmful resin odors.

The user-friendly design, including a 4-point leveling system and laser-carved build plate, makes the Jupiter SE a great choice for both beginners and professionals.

Customer Review

"The ELEGOO Jupiter SE has been a fantastic addition to my resin printing collection. The large build volume and high-quality prints make it perfect for my larger projects. The automatic resin feeding and recycling system is a great feature, saving me time and money." - John

The Best Choice for Large Format Printing

ELEGOO Jupiter SE Resin 3D Printer

3. ELEGOO Saturn 3

The ELEGOO Saturn 3 is known for its high accuracy and large build volume. With a 10-inch 12K monochrome LCD and a printing size of 8.62x4.84x9.84 inches, this printer is perfect for producing highly detailed models.

Exclusive Insights

The Saturn 3's 12K resolution ensures that every printed layer is accurate and detailed. The Voxeldance Tango Slicer offers multiple printing modes, improving print speed and efficiency.

The laser-carved build plate provides excellent adhesion, ensuring successful prints every time.

The Fresnel collimating light source and COB light source work together to produce consistent and accurate prints.

The Saturn 3 is compatible with third-party slicer software, giving you more flexibility in your printing projects.

Customer Review

"I've been using the ELEGOO Saturn 3 for a few months, and I'm impressed with its high accuracy and large build volume. The 12K resolution produces stunningly detailed models, and the Voxeldance Tango Slicer makes the printing process smooth and efficient." - Emily

High Accuracy and Large Build Volume

ELEGOO Saturn 3 MSLA 12K 3D Printer

4. ELEGOO Mars 4

The ELEGOO Mars 4 is an affordable option for those looking to get into resin printing. With a 7" 9K monochrome LCD and a printing size of 6.04 x 3.06 x 6.89 inches, this printer offers high-quality resin printing at a budget-friendly price.

Exclusive Insights

The Mars 4's 9K monochrome LCD provides high resolution and crisp details for your resin prints. The multiple print modes allow you to customize your printing process, ensuring the best results for your models.

The laser-carved build plate ensures excellent adhesion, reducing print fails.

The user-friendly UI and 3.5-inch touch screen make the Mars 4 easy to use, even for beginners.

The COB light source ensures consistent and accurate prints, making the Mars 4 a great choice for anyone looking to start resin printing.

Customer Review

"The ELEGOO Mars 4 has been a fantastic entry into resin printing for me. The high resolution and multiple print modes allow me to create detailed models with ease. The affordable price and user-friendly design make it a great choice for beginners." - Mark

Affordable and High-Quality Resin Printing

ELEGOO Mars 4 MSLA 3D Printer

Understanding the Curing Process: Tips for Perfect Prints

The curing process is crucial for achieving high-quality resin prints. Proper curing ensures that your models are strong and durable, reducing the risk of print failure.

Using UV light to cure your resin prints is essential for achieving the best results. Make sure to properly post-process your models to remove any excess resin and ensure a smooth surface.

Choosing the Right Resin: Different Materials for Different Needs

When diving into resin printing, selecting the right resin is crucial. Different materials cater to various applications, from standard resin for everyday prints to other resins designed for specific uses like jewelry or functional parts.

Standard resin is a great starting point for beginners, offering a balance of cost and quality.

However, for those looking to create models with high resolution and intricate details, other resins like flexible or tough resin might be more suitable.

Each type of resin has its unique properties, making it essential to choose the right one for your project.

Print Speed and Quality: Balancing Act for Resin Printers

Achieving the perfect balance between print speed and print quality is a common challenge in resin printing. High-quality prints often require slower speeds to ensure each printed layer is accurately formed, especially for highly detailed models.

However, some resin printers are designed to offer both speed and quality.

By adjusting settings and using advanced technology, you can produce high-resolution prints without sacrificing speed.

This balance is key to maximizing the efficiency and effectiveness of your resin printer.

Maintenance Tips: Keeping Your Resin Printer in Top Shape

Regular maintenance is essential to keep your resin printer running smoothly. Cleaning excess resin from the build plate and ensuring good ventilation are crucial steps in maintaining your machine.

Additionally, regularly checking for uncured resin and cleaning the vat can prevent print fails and extend the life of your printer.

By following these maintenance tips, you can ensure consistent performance and longevity for your resin printer.

Safety First: Handling Liquid Resin and UV Light

Handling liquid resin and UV light requires careful attention to safety. Always wear gloves and protective eyewear when working with uncured resin to prevent skin irritation and other health hazards.

Using a screen protector can also help shield your eyes from harmful UV light during the curing process.

Ensuring good ventilation in your workspace is another important safety measure to avoid inhaling fumes from the resin.

Summary

Each of the resin printers discussed offers unique features that make them stand out in the market. From high-resolution screens to advanced cooling systems, these printers are designed to provide high-quality prints and reliable performance.

Whether you're a beginner or a seasoned professional, these resin printers offer all the advantages you need to create stunning models. Their combination of technology, build volume, and user-friendly features make them a great choice for anyone looking to invest in a resin printer.

Frequently Asked Questions

1. What are the benefits of using resin printers over FDM printers?

Resin printers offer higher resolution and better print quality compared to FDM printers. They are ideal for creating highly detailed models and intricate designs.

2. How do I maintain my resin printer to ensure longevity?

Regular maintenance includes cleaning excess resin, ensuring good ventilation, and checking for uncured resin. Following these steps can help prevent print failures and extend the life of your printer.

3. What safety precautions should I take when using a resin printer?

Always wear gloves and protective eyewear when handling liquid resin. Use a screen protector to shield your eyes from UV light and ensure good ventilation in your workspace.

4. Can I use different types of resins with my resin printer?

Yes, resin printers are compatible with various types of resins, including standard resin, flexible resin, and tough resin. Each type has unique properties suitable for different applications.

5. How long does printer resin last?

While unopened resin can last up to 2 years, opened resin typically lasts around 6 months to 1 year, depending on storage conditions, proper storage is key to maintaining resin quality.

6. How expensive is resin?

The cost of resin for 3D printing can vary widely based on several factors, including the type of resin, brand, and quantity purchased. While standard resins are relatively affordable, specialty resins can significantly increase the cost. It's essential to consider the specific requirements of your printing project when selecting resin.

7. Do resin printers need curing?

Yes, resin printers require curing. After a print is completed, the resin model is typically not fully solidified and needs to undergo a curing process to achieve its final strength and stability.

8. Is resin printing stronger than 3D printing?

Resin printing and traditional FDM (Fused Deposition Modeling) 3D printing each have their strengths, and whether one is "stronger" than the other can depend on several factors:

1. Material Properties:

- Resin Printing: Typically, resin prints are made from photopolymer materials that can provide a smoother finish and higher detail. Certain resins, such as tough or high-strength variants, can achieve impressive mechanical properties and are often stronger in tension.

- FDM Printing: FDM printers use thermoplastic filaments like PLA, ABS, or PETG. These materials can be mechanically robust and are often better in terms of impact resistance compared to some resin types.

2. Layer Adhesion:

- Resin prints have exceptional layer adhesion due to the curing process, which can lead to overall stronger parts. However, they may be more brittle depending on the resin used.

- FDM prints may have weaker layer adhesion, which can affect overall strength, especially in parts with intricate designs or where layers may separate under stress.

3. End Use Cases:

- The choice between resin and FDM often depends on the intended application. For intricate detail and smooth finishes (like miniatures or jewelry), resin is preferred. For functional parts that endure mechanical stress, FDM with the right filament may be better.

4. Post-Processing:

- Resin prints generally require more post-processing (like washing and curing) to achieve optimal strength, while FDM prints can often be used straight from the printer, although they might benefit from sanding or coatings for strength.

In summary, whether resin printing is stronger than FDM 3D printing depends on the specific materials used and what properties are most important for your particular application.

9. Is it safe to use a resin printer indoors?

Using a resin printer indoors can be safe, but it requires taking specific precautions due to the nature of the materials involved. Here are some important considerations:

1. Ventilation:

- Resin printing can release fumes that may be harmful if inhaled. It's crucial to ensure that the area is well-ventilated. Using an exhaust fan or opening windows can help dissipate any fumes.

2. Personal Protective Equipment (PPE):

- When handling resin, it's advisable to wear gloves, goggles, and a mask to protect against skin contact and inhalation of fumes. Some resins can be irritating to the skin and respiratory system.

3. Storage:

- Store resin in a cool, dark place, away from direct sunlight and heat sources. Ensure that containers are tightly sealed to prevent leaks and exposure to air.

4. Spills and Cleanup:

- Be prepared for spills by having absorbent materials on hand. Clean up any spills immediately using appropriate cleaning agents, such as isopropyl alcohol.

5. Curing Process:

- The curing process can also release fumes, so ensure that this is done in a well-ventilated area. Some users prefer to cure prints outdoors or in a dedicated space away from living areas.

6. Children and Pets:

- Keep resin printers and materials out of reach of children and pets to prevent accidental exposure or ingestion.

In summary, while it is possible to use a resin printer indoors, it is essential to take proper safety precautions to minimize risks associated with resin fumes and handling.

Related Articles: